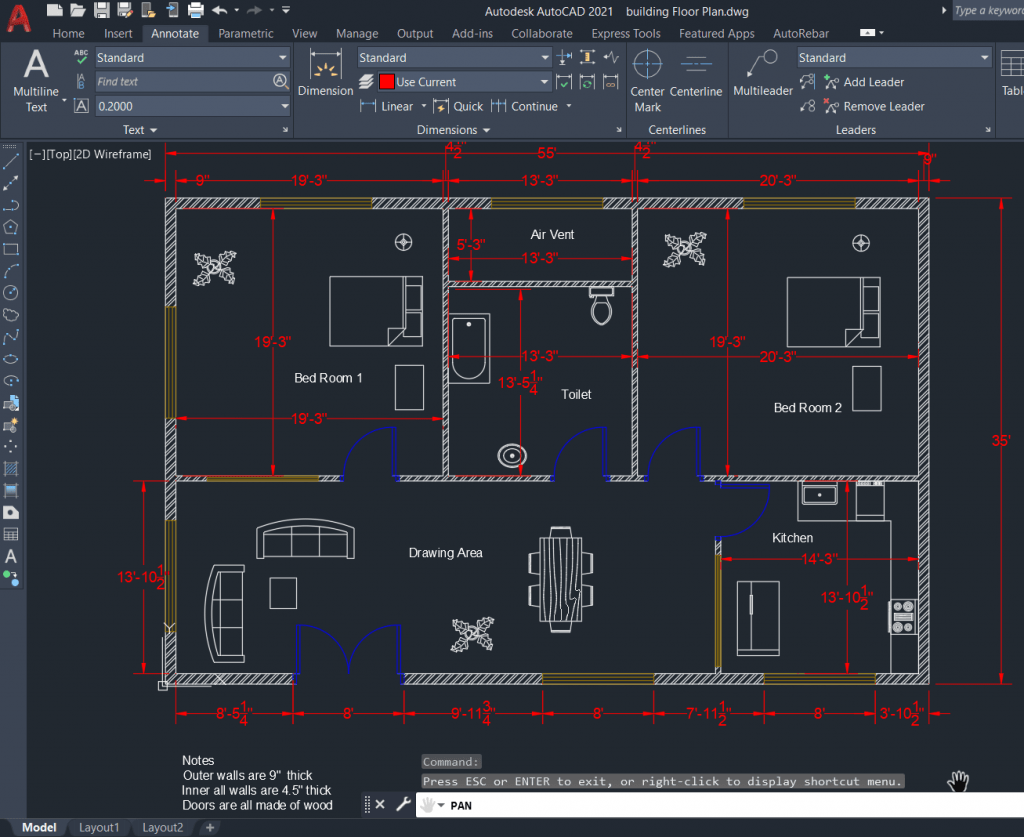

Particularly when combined with 3D scanning, computer aided design software can be an immensely useful tool for the most crucial steps along the QA/QI continuum, on the assembly line, at the loading dock, upon taking delivery, or out in the field.

One of today’s most potent uses of CAD is in quality inspection. Not only for protective purposes, such CAD-accurate packaging makes it possible to optimize space and reduce total shipping weight, significant factors when it comes to producing and shipping hundreds if not thousands of a given product over time. Having a precisely-dimensioned CAD model of your product makes it easier to produce inner packaging that cushions and protects the product, especially fragile and shock-sensitive items, with corrugated cardboard, foam, and microfoam as possible mediums.

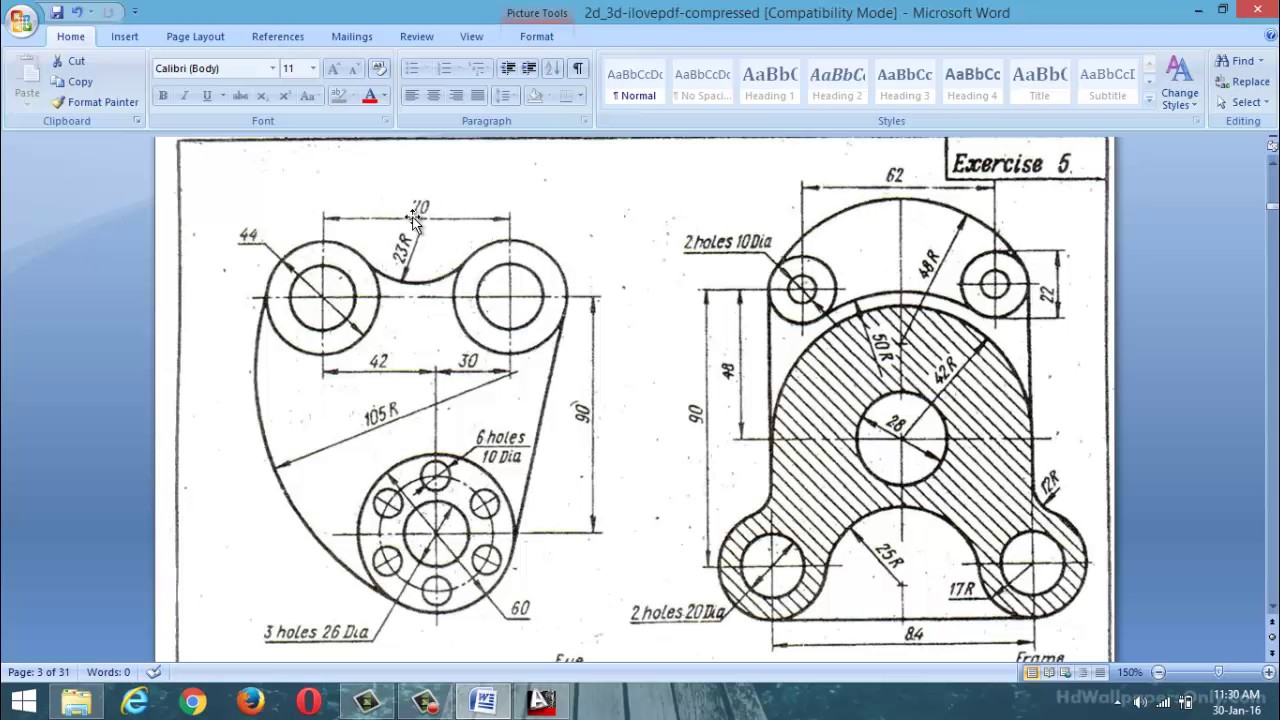

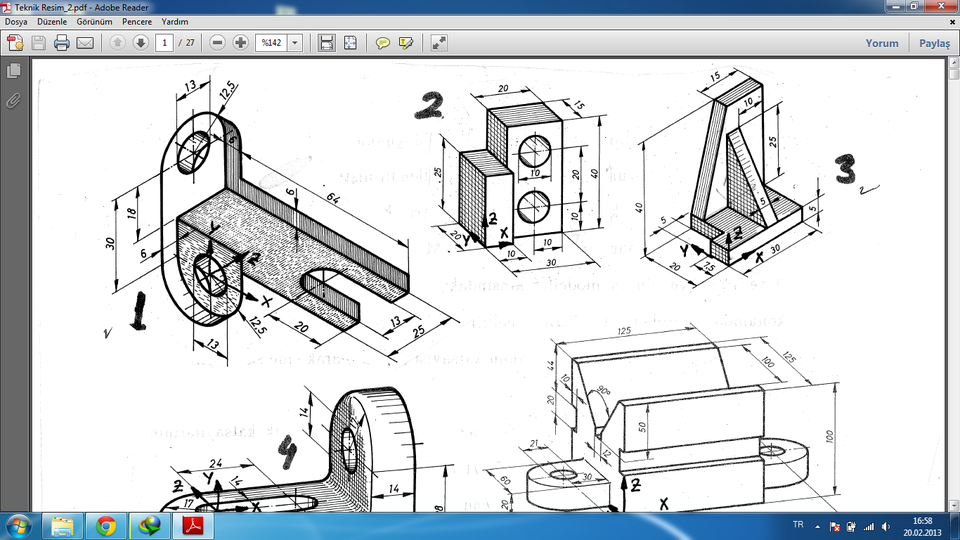

With your CAD model tested and ready for manufacturing, it can also be used for creating custom product packaging for shipment and well as display. Importing your CAD model into a CFD system gives you the power to conduct aerodynamic/hydrodynamic testing, a critical stage of the design process for many clients, from motorsports to aviation to maritime industries, and beyond. By taking your CAD model and bringing it over into one of these systems, you can perform essential stress and fatigue analysis testing, for analyzing and improving aerospace or automotive components, among others. FEA, CFD, and beyondĪnother potential avenue is a simulation, such as FEA (finite element analysis) or CFD (computational fluid dynamics) testing. For example, let’s say you want to quickly create a range of new prototypes with various kinds of modifications, maybe even scaled versions of the original, with additional components and features added on.īy starting off with your existing CAD model and designing from there, you’ll not only have a solid foundation for your work, but you’ll also shave days if not weeks off your prototyping workflow. Once you’ve created your CAD models, a wide range of usage possibilities exist, well beyond simply manufacturing. This makes your future design workflows that much easier and faster, dramatically reducing the time and effort needed to bring your plans to life. These can also include custom parts and accessories, such as in-house-designed electronics or fasteners, or off-the-shelf components.Īll of these can be simply dragged and dropped into your designs, as needed. And this is where computer aided design software shines all the more, giving you the power to easily build up templates and libraries of components that you’ll be using again and again. Most likely whatever you’re designing won’t be the one and only product you create. Choose from hundreds of possible angles at whatever levels of magnification you wish. When you’re working in 3D, your hands are never tied to a standard six-view layout. Unlike with drafting and 2D drawings, by using CAD software, you’ll never waste time with redrawing designs from scratch or creating new layouts from specific angles. Today’s computer aided design solutions give you the power to create models that precisely represent their real-world counterparts, within a few microns’ tolerance. There’s no way for the same to be done via 2D paper and pencil. From the initial concept and design stages, all the way through the analyses of components and assemblies, not to mention the actual manufacturing and packaging of the resulting products.īeing able to make changes to dimensions or shapes, whether minor or major, and then watch as those modifications propagate across the entire design in the blink of an eye, is of inestimable benefit to today’s modern design workflow. It can’t be emphasized enough just how much easier the design and engineering process is when using CAD software.

0 kommentar(er)

0 kommentar(er)